Water Operations

The City of Fresno delivers drinking water to more than 142,200 residential, commercial, and industrial customers over a 114 square mile area of the city including many county islands. With a staff of more than 190 full-time employees, the Water Division works 24 hours a day, 7 days a week to ensure that our customers receive clean, safe, and reliable drinking water.

Water Production and Treatment

The City of Fresno’s water system is a conjunctive use system, using both groundwater and surface water. The City maintains approximately 265 wells and has three surface water facilities that produce and treat the water that is delivered to customers.

GROUNDWATER TREATMENT OVERVIEW

Fresno has a long history of agriculture and industrial land uses. Chemical uses in those industries have led to successful production of crops and materials, but it has come at a price. Misapplication, past disposal practices, and a general lack of knowledge regarding the long-term environmental impacts of agricultural and industrial chemicals have led to impacts in groundwater quality in parts of the City of Fresno.

The State of California and the United States Environmental Protection Agency (USEPA) have set limitations and regulations on many contaminants detected in groundwater. The City must treat this water to meet safe drinking water standards. Contaminants sometimes exist in large underground plumes that impact multiple wells. Treatment ensures we can maintain safe water and adequate pressure in the local areas, minimize plume movement, and protect additional wells that might otherwise be negatively impacted.

Many of the health-based contaminants, being organic in nature, such as DBCP, PCE, TCE, 1,2,3-TCP, and PFAS compounds are fairly easily removed. The two most common treatment methods used are filtration through Granular Activated Carbon (GAC) and Packed Tower Aeration (PTA), also known as Air-Stripping. Both methods are very effective but are labor intensive and costly.

A few of the contaminants the City must treat for may be naturally occurring or caused by man-made activities such as septic tanks or fertilizer application. These include nitrates, manganese, iron, and hydrogen sulfide. The treatment methods for these contaminants can be as simple as blending water with other wells that are not impacted, or chemical treatment and filtration using chlorine and potassium permanganate.

Corrosion control treatment is another treatment method used at select wells. To help stabilize the differences between surface water and well water, orthopolyphosphate is added at well sites to help prevent corrosion to residential plumbing.

Lastly, sodium hypochlorite, commonly known as chlorine bleach, is added to the water as a disinfectant to protect the drinking water from harmful bacteria that could enter the system. The City’s target dose is 1.5 parts per million and is frequently not even noticed in the water.

SURFACE WATER TREATMENT OVERVIEW

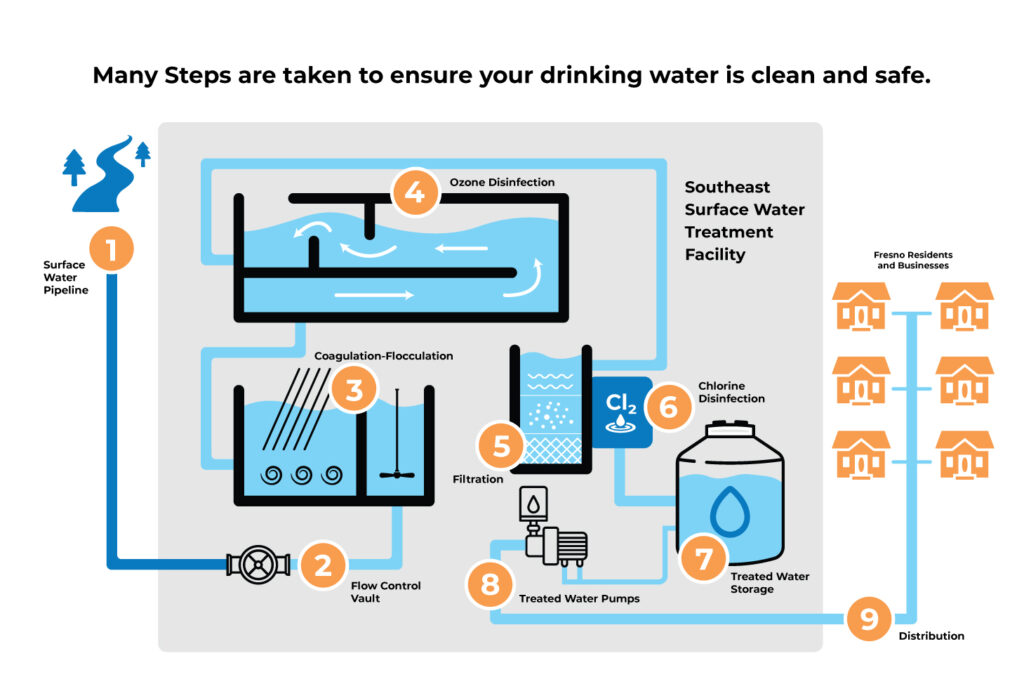

The surface water treatment process involves a series of steps to ensure that raw, or untreated, surface water is purified and sanitized to meet state and federal water quality standards before being delivered to customers.

Raw water is captured from nearby rivers and delivered to the treatment facilities through large-diameter water pipelines. A screen removes large objects before water enters the pipelines. Once at the treatment facility, treatment processes remove sediments, after which the water is filtered and disinfected before delivery to customers. There is little noise or odor associated with this water treatment process.

Distribution and Delivery

When water is pumped up from the aquifer or treated at the surface water treatment facility, it is distributed through a transmission grid main system to individual customers.

Our staff maintains, operates, and is involved in the construction of the water distribution system. The water distribution system comprises a vast network of water mains, water service connections, fire hydrants, valves, and water meters that deliver potable water to the houses and businesses within the City’s service boundary.

- 1,880 miles of distribution pipeline

- 140,500 service connections/water meters

- 13,000 fire hydrants

- 265 pump stations (wells)

- 3 booster pump stations

- 3 water storage tanks

- 20,697 isolation valves

Water Meters

Fresno has a contract to receive up to 60,000 acre-feet of high-quality water annually from behind Friant Dam. To comply with the terms of the Central Valley Project (CVP) water contract with the U.S. Bureau of Reclamation that supplies this water, the City must measure (meter) all water deliveries to customers. As a result, the Meter shop section of the Water Division maintains 140,500 water meters ranging in sizes from ¾ inches to 10 inches. Each meter has an automated meter endpoint, allowing for billing to be based on near real-time consumption. Other data such as leaks, tampers, and backflow can also be detected through the automated meter endpoints.

With the capabilities of the automated meter endpoints that have been installed at every residence in the City of Fresno, the City is able to monitor a property’s water usage on an hourly basis. Customers are also able to monitor their own property’s water usage through the EyeOnWater portal.

Cross Connection Control & Backflow

A cross-connection is an actual or potential unprotected connection between a potable water system and any other source or system through which it is possible to introduce contamination or pollution into any part of the City’s water system.

Backflow is any unwanted flow of used or nonpotable water, or other substances from any domestic, industrial, or institutional piping system, back into the potable water distribution system. The direction of flow under these conditions is opposite that of normal flow.

To ensure the safety of the water system, it is essential that physical cross-connections are eliminated. If a cross-connection is unavoidable, protection by installation of an approved backflow-prevention assembly becomes necessary.

The two most common types of backflow assemblies required by the City are the Reduced Pressure Principle (RPP) and the Double Check. There are other types of backflow devices, but these two offer the most resiliency for backflow prevention.

The Backflow section of the Water Division manages over 9,700 backflow devices across the city. Annual tests of these devices are mandated to verify they are working correctly to prevent the undesirable reversal of the flow of water or the mixture of water with other liquids, gases, or other substances in the distribution pipes of the potable supply of water from any source or sources.

Water Main Flushing (NO-DES)

Occasionally, the City needs to flush water mains to clear out sediment and keep the valves in good working order. The City has selected the Neutral Output Discharge Elimination System (NO-DES) system for flushing water mains, primarily because it does not waste our most valuable and precious resource: water. Instead of sending up to one million gallons of water out of fire hydrants and into gutters, the NO-DES unit filters and recirculates water inside the distribution main, allowing flushing to occur all year long. Additionally, the single direction flow and higher velocity means we can remove greater quantities of sediment and clean the mains better than ever before.

There are still instances where open flushing to the gutter is the preferred method. For example, short cul-de-sacs and dead-end lines typically have smaller blow-off fittings that limit how much water can be effectively circulated through the NO-DES trucks. Because of the initial time and labor needed to utilize the truck for each cul-de-sac or dead-end line, it is much more effective to openly flush these lines and, because most flushing runs are short, there is minimal water waste.

The City’s two NO-DES trucks are operated by two-person teams of employees who implement the seven-step process. The trucks rotate on a schedule and are in operation five days per week.

How It Works:

- Prep Work

A day or two prior to the NO-DES flush, a City valve-turning truck arrives, exercising the valves of the fire hydrants and water mains and cleaning debris from the service casings. Exercising valves regularly is important because it keeps the valves in good working order in case of emergency. - Easy Set Up

The NO-DES truck with an onboard filtering system parks between two fire hydrants in a neighborhood. - Connect

Workers connect a 5-inch hose from one fire hydrant to the filtering system and a second 5-inch hose to another hydrant. - Create Loop

Both fire hydrants are opened, filling the hoses and filters. This creates a temporary “loop” in the water distribution system. - Circulate

A large pump on the NO-DES unit circulates the water through the loop at a velocity of about three to five feet per second, stirring up debris and scouring the inside of the water main to remove sediments. - Filter & Purify

Nearly all sediment is removed as the water passes through the NO-DES filter. During this process, high-tech monitoring equipment on the truck allows the crew to check flow rates, pressure, water quality, and disinfectant levels. - Shut Down

When the entire section of water main in the zone has been filtered clean, the system is shut down, the hydrants are closed, the hoses are removed, and the City team leaves.

By opening and closing various main line valves in the area, staff can create different loops that can be flushed without having to move and set up the truck each time. This results in greater operational efficiency for the crew and a cost savings for our customers. The best part? We won’t have to shut off your water during the cleaning process, so you may not even know we were there!

Customer Notification

Prior to any activity in a neighborhood, residents are notified and made aware that the NO-DES truck will be in the area and are encouraged to reach out to City staff with any questions.

Additional Information

NO-DES Brochure

Door Hanger Notice

If you have questions about NO-DES, call (559) 621-5300.

SCADA, Instrumentation & Electrical

The Instrumentation, Electrical and SCADA (Supervisory Control & Data Acquisition) section has three sub-sections. Each plays a vital role in maintaining the Water Division’s technical devices and services ranging from, but not limited to, high horsepower electric motors to data servers.

Instrumentation

The Instrumentation section is responsible for installing, calibrating and maintaining various electronic monitoring and communication equipment, including pressure and level transmitters, programmable logic controllers, chemical analyzers, and computer aided operating systems at the City’s various surface water treatment plants and pump station (well) sites.

Electrical

The Electrical section is responsible for installing, repairing, and maintaining electrical components for large rotating equipment ranging from 50 horsepower to 200-plus horsepower, including associated motor control centers, programmable logic controllers, and variable frequency drive equipment.

SCADA

The SCADA group is responsible for administering, maintaining, and operating computerized distributed control, telemetry, and other computerized network systems. SCADA also oversees all computerized information activities including administration, programming, database administration, telemetry management, and instrumentation and control systems.